When constructing mixed-use and higher-density housing projects, fire-retardant lumber is increasingly required to meet local building codes. Though it is slightly more expensive than its untreated counterparts, the increased safety it provides is worth the investment.

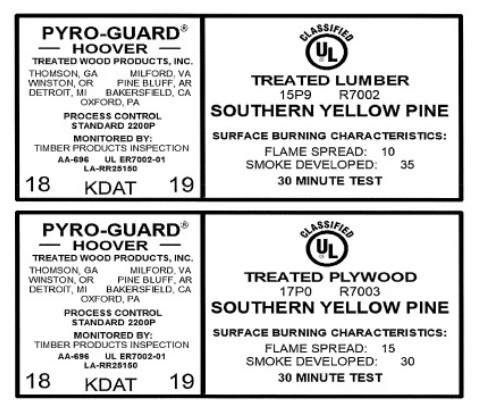

Similar to other types of construction materials, fire-retardant wood comes in a variety of types and ratings. Each piece will be stamped to indicate its quality and relevant information.

Following is an overview of how to read this stamp and be confident that your selected product material meets code requirements.

What Is Fire-Retardant Wood?

Fire-retardant wood (also called FRTW or fire-retardant-treated lumber) is lumber and plywood pre-treated with chemicals that reduce how quickly a fire can spread once it comes into contact with the plywood.

The chemicals used to treat FRTW are primarily salt-based and are infused into the cells of the wood using a vacuum chamber called a retort. In this way, the wood is treated throughout rather than simply coated on the surface.

How to Read a Fire-Retardant Wood Label

Each piece of fire-retardant wood is stamped once its treatment is complete. This stamp contains eight items that detail the attributes of that piece of plywood and inform buyers of its intended performance and durability in the presence of fire. Being able to read this label is the first step in confidently purchasing the correct FRTW for a project.

Each fire-retardant wood label will include the following information:

1. Treatment Company

Typically, the first element on every FRT wood label is the treatment company. This discloses who was responsible for putting the lumber in the retort and applying the chemicals. Some contractors prefer to work exclusively with certain treatment companies due to reputation or previous results.

2. Name and Location Information

Underneath the treatment company will be information about their location and the brand name of the product. This ensures that buyers know exactly which FRTW they are buying to avoid confusing one material from a certain company with another. This area also includes the manufacturing standards and standards-setting body the wood complies with.

3. Species

The species indicates the type of wood harvested to create the plywood. This information is essential to ensure the right product is chosen to meet necessary load requirements.

4. Treatment Method and Location

Next comes information about where the wood was treated and in what manner. This allows buyers to confidently understand whether the plywood was fully pressure impregnated with chemicals, whether it was coated, or something else.

5. Drying Method

Following treatment information (and often on the same or next line) are details about how the FRTW was dried. FRTW is kiln-dried after treatment (KD or KDAT) to speed up and control the drying process. Preservative treated wood is often left wet, but it can also be KDAT. This line also typically includes the year the drying occurred.

6. Third-Party Agency Information

An unbiased third-party agency is responsible for testing the FRT plywood to ensure it meets established industry standards, and this agency’s information will be displayed next. It may bear a name or simply a logo.

7. Flame Spread Index (FSI)

One of the most important elements of the FRTW label is the Flame Spread Index (or rating). The higher the number, the worse the material is at containing flame. A low flame spread index means flames will not move far beyond their point of origin.

|

Class |

Flame Spread Index |

|

A |

0 – 25 |

| B |

26 – 75 |

| C |

76 – 200 |

8. Smoke Developed Rating

The other key element of a label is the smoke developed index. This indicates how much smoke the wood will produce while burning. The lower the number, the less smoke the material produces in the event of fire, allowing people to escape more easily and permitting firefighters entry with less danger.

Learn More About FRT Plywood from Industry Professionals

Curtis Lumber & Plywood, founded in 1957, is an independently owned and operated wholesale lumber dealer exclusively serving premier lumber retailers throughout the mid-Atlantic and Southeast regions of the United States.

Based in Northern Virginia, we specialize in fire-retardant and preservative treated lumber and plywood for both indoor and outdoor applications. If you are a lumber retailer and have questions about plywood or treated wood products or need to place an order by the trailer load, unit or piece, contact Curtis Lumber & Plywood at 703-552-5778.